RockPly® – The Plywood Revolution That Boosts Your Profits

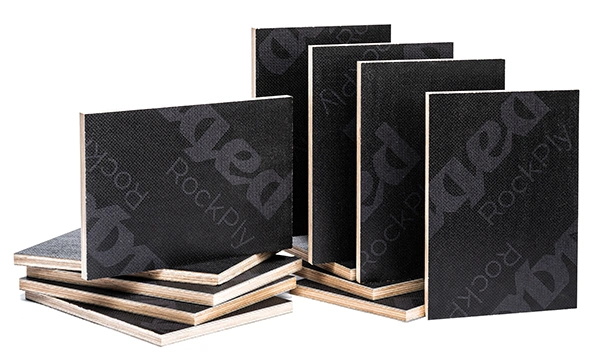

Discover the groundbreaking plywood reinforced with rock fibers. Lighter, stronger, and unmatched in the market – designed to reduce your costs and accelerate your projects.

Why is RockPly® the Best Investment for Your Business?

Twice the Strength of Standard Plywood - Reduces the risk of failures and repairs.

Lighter Construction – Lowers transportation costs and simplifies assembly.

Increased Durability and Weather Resistance – Longer service life and reduced replacement costs.

Lower Carbon Footprint – Meets environmental requirements and enhances your company’s image.

Minimal VOC Emissions, Including Formaldehyde –A safer work environment and higher occupational health standards.

Who Is RockPly® For?

Applications That Quickly Boost Your Profits

Construction and Infrastructure

RockPly® in load-bearing structures increases safety and shortens construction timelines.

Transportation (Trailers, Bodies, Containers)

Lighter loads mean lower fuel consumption and reduced CO₂ emissions, translating to real financial savings.

Defense and Military Industry

High strength and low weight enable easier logistics and safety in extreme conditions.

Events and Industrial Platforms

Quick assembly and disassembly, fewer personnel needed, and lower risk of damage.

Specialist Packaging

Customizable sizes and thicknesses optimize storage and transportation costs.

Key Technical Features That Deliver Real Benefits

- Formats (1250×2500 mm, 1500×2500 mm) and Thicknesses (6.5–30 mm) – Production flexibility and time savings during processing.

- Bonding Class 3 (EN 314-2) – Reliability in outdoor conditions, reducing the need for repairs and sealing.

- Minimal Emissions (0.003 ppm Formaldehyde) – A safer workplace, suitable for confined spaces.

- Water Resistance and Enhanced Thermal Insulation – Stability and longer product lifespan in tough conditions.

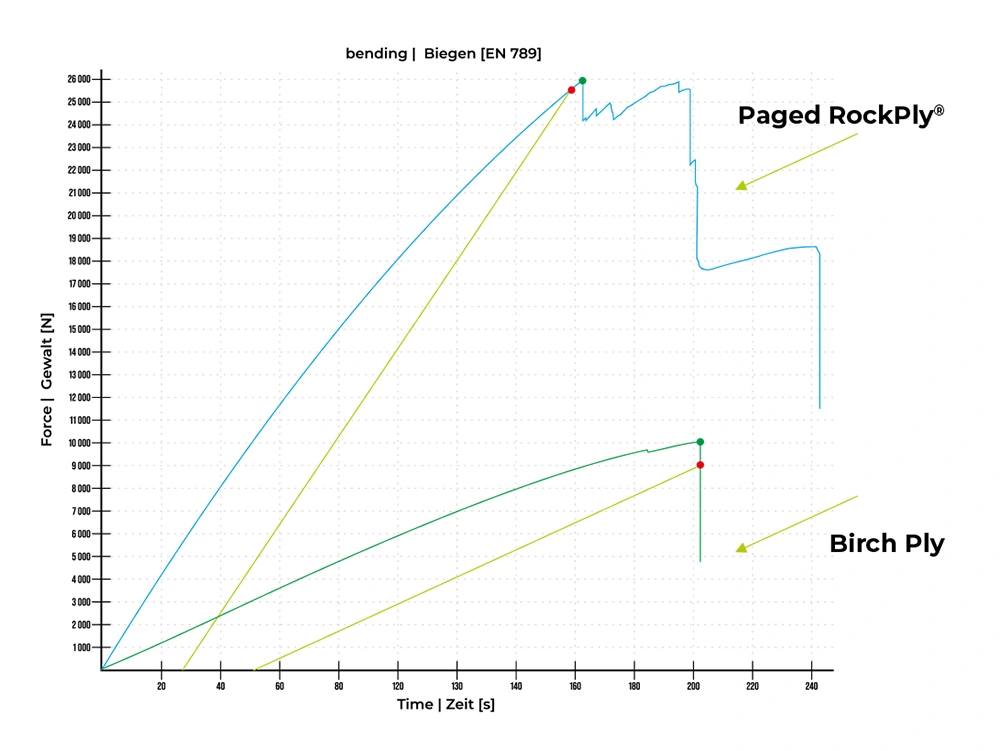

RockPly®

No sudden fractures under static load, unlike traditional birch plywood. RockPly® requires significantly more force to break, ensuring superior durability.

BirchPly

Shear Strength (EN 314) – Comparable shear strength to BirchPly (approximately 1.5 N/mm²), with no adverse effect on bonding quality.

Join the Plywood Revolution Today!

Paged RockPly® sets new industry standards. By choosing RockPly®, you gain a competitive advantage, reduced costs, and the assurance of working with an established market leader.

Contact Us and Outperform the Competition!

Fill out the form to schedule a consultation. Our team will recommend the best solution tailored to your industry and needs while answering all technical questions.

Why Trust Us?

Expertise, Experience, and Innovation – Your Success Guaranteed

- Paged boasts over 90 years of experience and ranks among the top five plywood manufacturers in Europe.

- With our own research and development center (Paged LabTech), we create the market’s most innovative products.

- Our extensive experience and numerous certifications ensure reliable support for our clients at every stage of collaboration.

Construction Plywood… and More for the Building Industry!

Paged, a leader in the production of construction plywood, proudly presents its latest offering – a series of pine plywood that provides an innovative solution for even the most demanding customers. This new product line, which includes five specialized types of plywood, has been designed with unparalleled durability, safety, and ecological efficiency in construction in mind.

Paged’s product portfolio includes raw hardwood and softwood plywood, coated and film-faced plywood, fire-resistant plywood, as well as specialized products such as ELKON®.